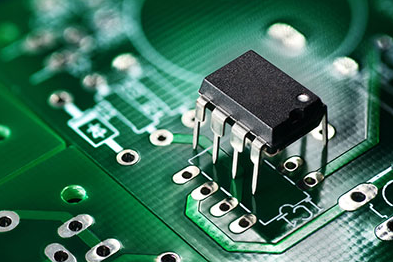

Welcome to the new post, readers. Through Hole Technology and its Applications will be explained in this post. With the help of a soldering iron and holes on the PCB board, the components of the project are assembled. With through-hole, older methods of joining apct.com components that are point-to-point have to be replaced with through-hole techniques.The use of through-hole techniques for component assembly was prevalent in the 1980s when second-generation computers transitioned to SMT techniques.

It was originally just one side of the board used for creating projects, but now both sides are used to create multilayer boards. A plated through-hole was used to connect components to certain copper layers on the boards. Vias are connections between layers made with PHT.We will learn about the advantages, disadvantages, etc. of through-hole technology here.

How does Through Hole Technology work?

- The boards are assembled with leads. The first type of lead is axial, and the second type is redial.

- As a result of assembly, axial leads resemble cylinders, and an axis is a connecting component.

- Over the surface of the board, radials are arranged in parallel configuration.

- Basically, it’s the radius of the circle where different components of a circuit are positioned.

- With the use of radial leads, the circuit has a high density and creates a physical display like a 90-degree angle.

- By moving the leads in U shape, we can obtain the required structure for converting an axial connection to a radial connection.

- Make sure that there are no connections between the board components during this process.

The process of drilling through holes is less expensive

- It saves time and money by eliminating the need for making new solder stencils.

- The technique is considered a cost-saving technique because it makes circuits at a lower cost than other techniques.

- Compared to through-hole SMT, SMT requires new components to be processed.

- In addition to saving costs, manual testing is performed for this process.

- It is a cost-effective technique using tin-lead solder. The board can be found by finding any bends or twists.

Through Hole Service: How to get it

- PCB and Through-hole services are offered by numerous companies at different rates, but the JLCPCB is one of the best and most reliable service providers. I think JLCPCB offers a very cost-effective solution, along with excellent customer support. I was able to produce the PCB in only a few days with good quality and low price service from them.

- With SMT, they offer through-hole service. Another great service that JLCPCB offers is the ability to solder through-hole components alongside SMT components. This time, the SMT quality was excellent. These combicon connectors are not soldered so straight, which causes a minor problem.

- You can get all details about your products from their customer service team. You can get a detailed overview and final delivery timeline for the component through the hole.They should be able to fulfil all your requirements to get the products you need.

The features of through hole technology

- SMT gives strong mechanical joining, which requires extra drilling and increases board cost.

- On multilayer boards, they used to restrict the routing area to the layers immediately below the upper layers.

- Semiconductors, capacitors, and other large-sized components are made using through-hole techniques.

- In larger packaging, such as TO0-220, this technique was used for elements such as plug connectors that required extra mounting strength.

- In prototyping, through-holes are used since breadboard sockets can be attached.

- For prototyping circuits using microprocessors like Arduino, through-hole elements are ideal.

Leave a Comment

You must be logged in to post a comment.