CNC carbon fiber is special and useful because of its many appealing features. Carbon fiber, when used properly, can lessen the load and slim down the overall appearance of a device. Simultaneously, it improves the structure’s stability and robustness. Take a look at these five innovative uses of carbon fiber sheets later in this post.

What Are Carbon Fiber Sheets?

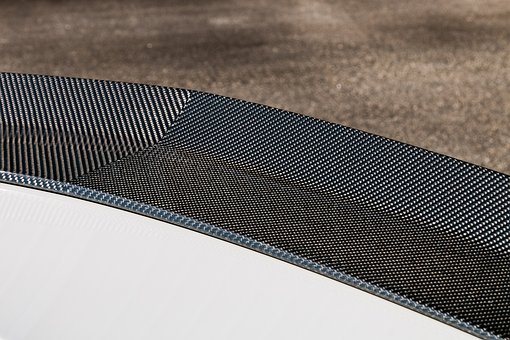

Carbon fibre sheets, also called composites, are made by curing a fabric made of carbon fiber that has been coated with epoxy resins. Multiple pieces of fabric are sewn together to form a sheet, which can vary in size, thickness, and weave. Sheets work best on level surfaces due to their flat shape. The rigidity of a sheet increases with its thickness.

There is a wide variety of weaves, and they all look, feel, and perform differently. Some weaves are strong but not as flexible as others. Some are sophisticated yet weak.

For instance, looser weaves are more flexible and can be shaped to fit unusual shapes. However, it is less stable and more prone to developing gaps between the fibers.

Think about how the sheet will be used and how it will be displayed before purchasing carbon fiber sheets. Sheets of carbon fiber are available at several locations, and these companies also offer expert guidance. In addition to their standard carbon fiber sheets, they also carry a sample pack that includes squares of 4 x 4″ in various thicknesses and rigidities of their high-gloss, mirror-finish carbon fiber parts, and sheets.

Automotive Applications

Carbon fiber’s exceptional strength-to-weight ratio makes it perfect for use in high-performance automotive applications. The McLaren MP4/1 Formula One race car was the first to include a carbon fiber chassis, which debuted in 1981. Since then, this lightweight material has been all the rage in the automotive industry.

Many components benefit from its lightweight and high strength-to-weight ratio. However, composite sheets have become popular in the interiors of high-end automobiles due to their desirability from an aesthetic standpoint.

Customizing your car for a sleek, sporty style is easy with carbon fiber sheets. The most usual cosmetic applications are:

- Gearshifts

- Door panels and pillars

- Sound system and speaker fronts

- Instrument panels and dashboards

- Gas caps

- Mudflaps

- Vents

Also, you have the option of having a carbon fiber automobile badge custom-crafted to replace one made of metal or plastic. Speak with your provider about the availability of cutting and milling services.

Personal Items

Carbon fiber presented certain challenges during early development. A few years ago, however, accessories began to rise in favor as composites and forged carbon fiber became more practical and user-friendly. Today, it’s all the rage amongst designers. The reason why it is so is clear-cut.

The distinctive patterns of the fibers are used to make eye-catching accessories, including jewelry, watches, wallets, and garments. Also, aesthetics are not the only factor. Lightweight, long-lasting, and hypoallergenic sum up the benefits of carbon fiber accessories.

You can take your look to the next level by accessorizing with a piece made of a hybrid of two different materials. For example, put your cards in style with a Cardissimo business card case or pin your keys to your belt with a lightweight carbon fiber carabiner.

Furnishings and Home Design

Carbon fiber composites are used in a wide variety of products, from clocks to cookware. Assuming the surface is flat, carbon fiber sheets can be used for both aesthetic and practical purposes, such as in automobile customization.

Because of its numerous exquisite sheens and cutting-edge weave patterns, carbon fiber is a favorite among designers. A high-gloss finish, on the other hand, can amplify the dimensions and create an illusion of depth, making it seem as though the weave can be felt.

However, due to its lightweight nature, carbon fiber may be used in the furniture industry.

Equipment for Sports

Carbon-fiber equipment is the best option for athletes. Many advancements were made in the decade before the turn of the century, and improved fabrication techniques made them accessible to professional athletes.

Since then, there has been no slowdown in the production of composite carbon fiber materials for use in making lightweight athletic products.

However, carbon fiber has lately improved snowboards. Plates made of carbon fiber can spread the load more evenly. This allows for a more natural board flex. You can get a board with the flex you want, and there are even boards that can be custom-made. Furthermore, it is extremely tough to break.

Hobbies That Involve Carbon Fiber Sheets

The qualities of carbon fiber composite make it a wonderful choice for a wide range of hobbies. It’s less heavy than aluminum, more durable than steel, and electrically conductive. Additionally, it has little thermal expansion and can reduce vibrations. Both experienced DIYers and novices can benefit from working with carbon fiber sheets.

Drones

There are numerous benefits to using composite sheets when designing drones. Carbon sheets are simple to cut and shape, eliminating the need for expensive mold creation. Furthermore, drones are quite weight-dependent. Benefits of carbon fiber include increased flight time, maneuverability, strength, and payload (cameras, etc.) capacity.

Robotics

Fans of robotics tend to prefer carbon fiber sheets on flat surfaces to just about any other material. The lightweight sheets allow for quicker motion with minimal effort. It’s cheaper than most alternate solutions as well.

Aviation

Aircraft kits allow you to assemble high-performance aircraft in the comfort of your own home. Composite aircraft building is not new, but recent advances have made it greatly easier and faster to put together.

The newer models have lighter carbon fiber construction compared to the usual fiberglass.

These are just a few of the various applications of carbon fiber. The actual limit is your own imagination. Always go for the best quality when shopping for Carbon Fiber Molding, Carbon fiber veneer, carbon fiber sheets, or other items, or find a manufacturer who has experience with carbon composites. Once you get your hands on some carbon composite, you’ll want to use it for everything, whether you’re working on a specific project or just browsing for eye-catching goods.

Leave a Comment

You must be logged in to post a comment.